Best scaffolding prop supplier

Our scaffolding steel columns are available in two main types to meet different load requirements. The lightweight struts are made from smaller sized scaffolding tubes with an outer diameter of 40/48 mm, making them ideal for light duty applications. Not only are these props lightweight, they are also strong and durable, ensuring they can support your project without compromising safety.

At our company, we understand the importance of quality and reliability in building materials. That's why we source only the best materials and employ strict quality control measures throughout the manufacturing process. Our commitment to excellence allows us to expand our global reach. Since establishing our export company in 2019, we have successfully served customers in nearly 50 countries, providing them with best-in-class scaffolding solutions tailored to their specific needs.

Whether you're a contractor, builder or DIY enthusiast, our scaffolding steel prop are designed to give you the support you need for any project. With our extensive experience and dedication to customer satisfaction, we believe you will find our products to be the best on the market.

Basic information

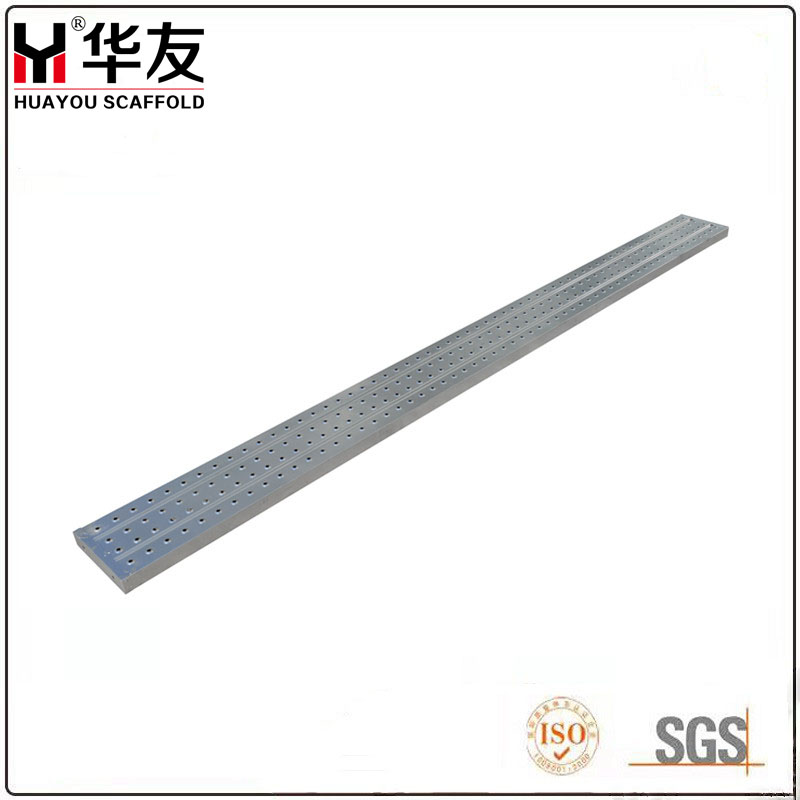

1.Brand: Huayou

2.Materials: Q235, Q195, Q345 pipe

3.Surface treatment: hot dipped galvanized , electro-galvanized, pre-galvanized, painted, powder coated.

4.Production procedure: material---cut by size---punching hole---welding ---surface treatment

5.Package: by bundle with steel strip or by pallet

6.MOQ: 500 pcs

7.Delivery time: 20-30days depends on the quantity

Specification Details

|

Item |

Min Length-Max. Length |

Inner Tube(mm) |

Outer Tube(mm) |

Thickness(mm) |

|

Light Duty Prop |

1.7-3.0m |

40/48 |

48/56 |

1.3-1.8 |

|

1.8-3.2m |

40/48 |

48/56 |

1.3-1.8 |

|

|

2.0-3.5m |

40/48 |

48/56 |

1.3-1.8 |

|

|

2.2-4.0m |

40/48 |

48/56 |

1.3-1.8 |

|

| Heavy Duty Prop |

1.7-3.0m |

48/60 |

60/76 |

1.8-4.75 |

| 1.8-3.2m | 48/60 | 60/76 | 1.8-4.75 | |

| 2.0-3.5m | 48/60 | 60/76 | 1.8-4.75 | |

| 2.2-4.0m | 48/60 | 60/76 | 1.8-4.75 | |

| 3.0-5.0m | 48/60 | 60/76 | 1.8-4.75 |

Other Information

| Name | Base Plate | Nut | Pin | Surface Treatment |

| Light Duty Prop | Flower type/

Square type |

Cup nut | 12mm G pin/

Line Pin |

Pre-Galv./

Painted/ Powder Coated |

| Heavy Duty Prop | Flower type/

Square type |

Casting/

Drop forged nut |

16mm/18mm G pin | Painted/

Powder Coated/ Hot Dip Galv. |

Main features

1. Durability: The main function of scaffolding steel pillars is to support the concrete structure, formwork and beams. Unlike traditional wooden poles that are prone to breakage and rot, high-quality steel pillars have higher durability and service life, ensuring the safety of construction sites.

2. Load Capacity: A reliable supplier will provide props that can withstand huge weight loads. This is critical to maintaining structural integrity during concrete pours and other heavy-duty applications.

3. Versatility: The best scaffolding props are designed to be versatile and meet a variety of construction needs. Whether you use plywood or another material, a good supplier will have props that can adapt to different project requirements.

4. Compliance with Standards: Ensure suppliers comply with industry standards and regulations. This not only ensures the quality of the product, but also ensures the safety of the site.

Product Advantage

1. Quality Assurance: The best scaffolding pillar suppliers prioritize quality, ensuring that their products, such as steel pillars, are durable and reliable. Unlike traditional wooden poles, which are prone to breaking and rotting, steel struts provide a strong support system for formwork, beams and plywood, significantly improving construction site safety.

2. Diverse product range: Reputable suppliers will usually offer a variety of scaffolding props suitable for different construction needs. This variety allows contractors to select the most appropriate props for their specific projects, increasing efficiency and effectiveness.

3. Global Reach: With our experience exporting to nearly 50 countries, we understand the nuances of international markets. Suppliers located around the world can provide in-depth knowledge of local regulations and standards, ensuring compliance and smooth operations.

Product shortcoming

1. Cost Variation: While high-quality scaffolding prop are essential, they can be expensive. Some suppliers may offer lower cost options, but these may compromise quality and safety, resulting in potential risks on site.

2. Supply Chain Issues: Working with international suppliers can sometimes cause delivery delays due to logistical challenges. It’s critical to evaluate a vendor’s reliability and track record of meeting deadlines.

3. Limited Customization: Not all vendors offer customizable solutions. If your project requires specific dimensions or features, you may find it challenging to source the right props from certain suppliers.

Application

1. One of our flagship products is the scaffolding steel struts, designed for formwork, beams and various plywood applications. Unlike traditional wooden poles that are prone to breakage and rot, our steel posts offer unparalleled durability and strength. This innovation not only enhances safety on construction sites but also increases efficiency, allowing contractors to focus on their core tasks without having to worry about equipment failure.

2. Our scaffolding steel pillars are used in a wide range of applications. They are ideal for supporting concrete structures during the curing process, ensuring that the building's integrity is maintained. By choosing our products, contractors can significantly reduce the risk of accidents and delays, ultimately achieving a more streamlined construction process.

Why choose steel instead of wood

The transition from wooden poles to steel struts revolutionized the construction industry. Wooden poles deteriorate easily, especially when exposed to moisture during the concrete pouring process. Steel struts, on the other hand, offer a strong and long-lasting solution that significantly reduces the risk of structural failure.

What should you look for in a scaffolding prop supplier

1. Quality Assurance: Ensure suppliers adhere to industry standards and provide high-quality materials.

2. Experience: Suppliers with a proven track record and experience in the market are more likely to effectively meet your needs.

3. Global Reach: Suppliers serving multiple countries can provide insights into various market needs and trends.

FAQ

Q1: How do I know which scaffolding props are right for my project?

A: Consider the weight and type of materials you will use, as well as the height of your structure. Consulting a supplier can help you make the best choice.

Q2: Are steel props more expensive than wooden props?

A: While the initial investment may be higher, the long-term benefits of durability and safety make steel props a cost-effective option.